Presented by Robin Whittle

History and Background

Sheep Pasture Top is situated at the western end of the Cromford & High Peak Railway at the top of the Sheep Pasture Incline, which rises around 500 feet from Cromford Goods Yard.

Sheep Pasture Incline was formed from Sheep Pasture and Cromford inclines which were combined to form the present incline on which working as one incline began on 16th October 1857. The present incline rises at 1 in 9, and then 1 in 8, for a distance of 1320 yards. Haulage is by means of a continuous rope, which is 2880 yards long. At the bottom the rope runs underground and is passed round a large pulley, situated in a pit built beneath the running tracks. At the top, the rope again goes underground, into the winding engine house, which is at the left-hand side of the line, as the wagons approach the summit. Inside the engine house the rope passes round a large pulley, 14 ft 1in in diameter, after which it passes round the driving pulley, which is the same size and is vertically underneath the loose pulley. This method increases the arc of contact between the rope and the driving pulley and also avoids any reverse bends in the rope.

The winding engine at Sheep Pasture Top, until 1964, was a relatively modern twin cylinder type, which drives the original flywheel and pulley through bevel gears. It was built in 1883, and its cylinders of 17 in bore by 24 in stroke are supplied with steam at 80lbs per square inch from an old LNWR ‘DX’ locomotive boiler, which is fired mainly with wood.

The wagons are attached in ‘runs’ to the wire ropes by means of tapering chains, which are plaited round the rope and their ends secured by leather straps. The maximum permitted weight of a run is 38 tons, and the weight of the descending run is usually arranged to be slightly more than the corresponding one ascending. In this way, the engine is only necessary for controlling the speed of the run.

Signaling on the incline is primitive but effective. Although an ex LNWR semaphore signal is situated at the top of the incline, it is no longer used, and a series of bells and pointers at the top and bottom of the incline are connected by wires. The pointer in the engine house at Sheep Pasture Top had three positions, one being ‘B’ for Stand By, ‘G’ for Go, and ‘S’ for Stop. The bells are arranged to ring when the pointer is moves.

At Sheep Pasture Top, an engine shed was provided for the locomotive working between there and Middleton Bottom. The original shed, probably built of timber, was replaced sometime before 1920 by a longer corrugated iron structure, but that was destroyed by a gale in 1962. Duties on the Sheep Pasture – Middleton section were lighter than elsewhere on the C&HPR line, and so older or less powerful locomotives were normally out-stationed there. From Sheep Pasture Top, the C&HPR continued almost on the level for over 1.25 miles to the foot of the Middleton Incline. This section was liberally sprinkled with quarry workings, a number of which had siding connections, but several of the quarries had fairly brief operational lives and their sidings were abandoned or removed. In later years, the principal working in the immediate area was Middleton Quarry (formerly Killers Quarry), which was served by a 0.75mile long branch. This was the property of the quarry company, but was worked by the regular Sheep Pasture – Middleton locomotive.

On 3rd June 1963 Middleton Incline was closed. From this date the C&HPR operated as two isolated sections. Traffic on the Sheep Pasture Top section going down Sheep Pasture Incline, however, amounted to 60,785 tons in 1961. It was stated that quarries in the same area had limestone deposits sufficient for the next 100 years and it was expected that the rail traffic would be increased to 100,000 tons a year which justified retention of Sheep Pasture Incline. The old ‘DX’ engine and winding equipment could have been repaired at a cost of £6,500 but it was estimated that all the 13 ton wagons would be withdrawn by 1970 and that the ability to handle only one 16 ton wagon at a time would necessitate double shift working and artificial lighting for working after dark. It was proposed to replace the winding machinery by electrical gear with a capacity of 100 tons, or four loaded 16ton wagons. So the old steam engine and boiler were replaced by an electric motor installed at a cost of £31,000 by John Boyd & Co (Engineers) Ltd of Annan, and brought into use in September 1964.

While this work was in progress traffic from Middleton quarry was worked by road down to Wirksworth where it was loaded into 25ton hopper wagons. These could not be used on Sheep Pasture incline because of the narrow width between the tracks. The operation proved so much more economical that was eventually decided to work it all via Wirksworth and out by the former Midland branch to Duffield. The last wagons were worked down Sheep Pasture incline on 1st April 1967.

The Layout

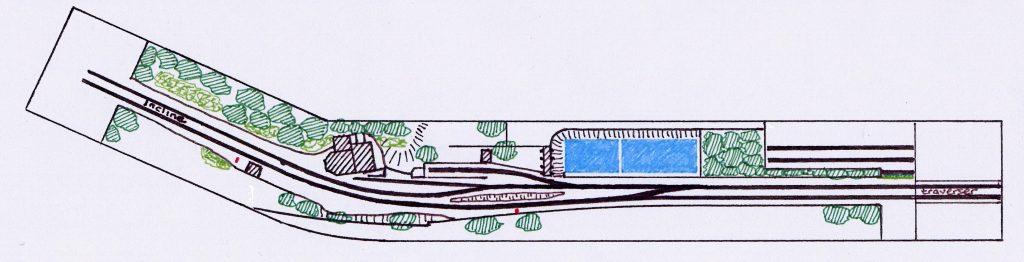

Size of Layout: 19 ft x 6 ft overall including operating space

It’s summer 1962. High above the hillside above the village of Cromford in Derbyshire, a faint plume of smoke rises above the skyline as a small tank engine passes Black Rocks, running bunker first with a mixed rake of empty water tenders and full mineral wagons, with limestone from Killer’s Quarry at Middleton.

The train’s destination is Sheep Pasture Top, head of the incline down to the eastern end of the line at Cromford Wharf.

On arrival, the locomotive, 47007 (James Bond to some local children) runs round its train and propels it toward the top of the Sheep Pasture Incline. Once over the small hump opposite the single road corrugated-iron engine shed (blown down earlier in the year), the brakes are pinned to bring the train to a gradual halt short of the incline. The first two wagons are uncoupled and nudged forward to rest against the scotch blocks at the brow of the incline. Here, they are attached with chains to the incline cable by the ‘hanger-on’, prior to their cautious descent to Cromford Wharf. The locomotive is uncoupled and drifts back over the cross-over adjacent to the two reservoirs, then sets back alongside the water tank. Here, the engine is left to simmer gently in the afternoon sun as the crew lift the lid of the water filler, insert the bag from the water column and replenish the saddle tank from the old cylindrical boiler, supported on brick columns, situated outside the engine shed – the High Peak’s version of the familiar water tower.

The layout has been built in an attempt to recapture the above scene as accurately as possible. It includes a fully detailed model of the stationary engine house, situated at the top of a working incline. Sheep Pasture can be displayed in two forms, one covering the period up to 1962 whilst the locomotive shed was still standing, and the other from 1962 until closure in 1967 with the shed dismantled following the storm damage. Sheep Pasture has won a number of awards and was featured in Model Railway Journal Nos 181 and 182.